X-Ray Protective Lead Rubber Screen: Ensuring Safety in Radiology

The modern world of medicine is hastily advancing, particularly in the field of radiology, where imaging technologies such as X-rays are critical for accurate diagnosis and treatment planning. However, with the immense benefits of these technologies come inherent risks associated with radiation exposure. To mitigate these risks, the use of x-ray protective lead rubber screens is pivotal. This article delves into the significance, applications, and benefits of these protective devices, aiming to provide a comprehensive understanding for professionals and stakeholders in the field.

Understanding X-Ray Radiation

X-rays are a form of electromagnetic radiation, similar to visible light but with much higher energy. Their ability to penetrate various materials, including human tissue, makes them invaluable for imaging bones and internal structures. However, this same property also necessitates stringent protective measures to safeguard against potential health hazards, such as:

- Cellular Damage: Excessive exposure to radiation can lead to cellular mutations and increase the risk of cancer.

- Acute Radiation Syndromes: High doses can cause immediate health issues.

- Protective Protocols: Importance of utilizing protective barriers during imaging processes.

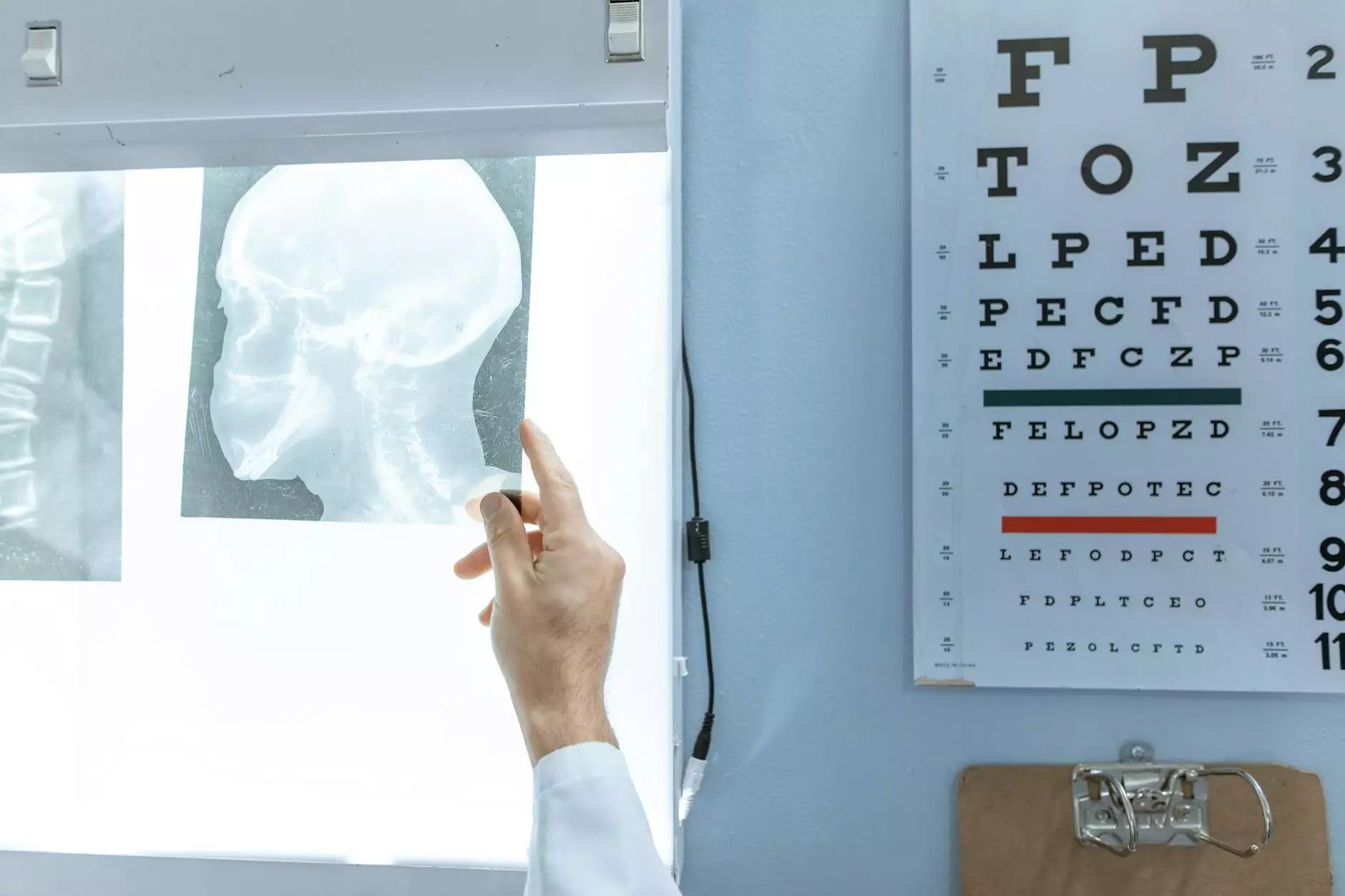

What is an X-Ray Protective Lead Rubber Screen?

An x-ray protective lead rubber screen is a specialized barrier designed to protect both patients and healthcare professionals from harmful radiation during X-ray procedures. These screens are made from a composite of lead and rubber, combining the radiation-absorbing properties of lead with the flexible and durable characteristics of rubber. This design not only enhances protection but also allows for easy manipulation and positioning, adapting to various clinical environments.

How Do X-Ray Protective Lead Rubber Screens Work?

The efficacy of x-ray protective lead rubber screens lies in the dual properties of their materials. Lead acts as an effective shield that absorbs and attenuates X-ray radiation, while rubber provides flexibility and mobility. Key features include:

- Radiation Absorption: Lead has a high atomic number, which makes it an excellent material for absorbing X-rays.

- Durability: The rubber exterior protects the lead from degradation and impacts.

- Mobility: These screens can be easily moved and adjusted, facilitating their use in various medical procedures.

Benefits of Utilizing X-Ray Protective Lead Rubber Screens

The implications of using x-ray protective lead rubber screens extend far beyond mere compliance with safety regulations. Some of the cardinal benefits include:

1. Enhanced Safety for Patients

For patients undergoing imaging, the primary concern is exposure to radiation. By implementing protective screens, healthcare facilities can minimize this exposure effectively. The lead rubber screens work as a barrier that absorbs harmful rays, ensuring that patients receive safe imaging services.

2. Protection for Healthcare Professionals

Healthcare professionals are at a continuous risk of radiation exposure, especially those working in radiology departments. The integration of x-ray protective lead rubber screens into clinical settings significantly reduces these risks, providing a safer working environment.

3. Compliance with Safety Regulations

Regulatory bodies mandate certain safety standards to protect both patients and healthcare providers from radiation hazards. Using these screens can help medical facilities comply with these regulations, avoiding potential fines and enhancing their reputation.

4. Versatility Across Applications

The versatility of x-ray protective lead rubber screens allows them to be utilized in various medical scenarios, including:

- X-ray procedures in hospitals and clinics

- Dental radiography

- Veterinary imaging

- Research laboratories involving radiation

5. Cost-Effectiveness

Investing in high-quality protective equipment, such as x-ray protective lead rubber screens, can lead to long-term savings. By reducing the incidence of radiation-related health issues among staff and patients, medical facilities can avoid costly health care costs arising from radiation exposure injuries.

Applications of X-Ray Protective Lead Rubber Screens

The applications of x-ray protective lead rubber screens are broad and impactful. They belong in multiple facets of healthcare, including:

1. Clinics and Hospitals

In hospitals, these screens are indispensable in radiology departments, where they are positioned strategically during imaging procedures to protect both patients and staff.

2. Dental Practices

Dentists often use X-rays for diagnostics. Installing lead rubber screens protects patients from unnecessary exposure while providing a clear field of vision required for accurate imaging.

3. Veterinary Clinics

Veterinary practices employ X-ray imaging for diagnostic purposes in animals. Utilizing x-ray protective lead rubber screens helps minimize radiation exposure to staff handling the pet patients.

4. Research Laboratories

In research, especially when dealing with radiation, the application of these screens provides safety for researchers working with X-ray equipment, thereby fostering an environment where inquiry and innovation can flourish without compromising safety.

Choosing the Right X-Ray Protective Lead Rubber Screen

When selecting x-ray protective lead rubber screens, healthcare providers should consider a number of factors to ensure optimal protection and functionality:

1. Lead Equivalent Thickness

The effectiveness of radiation shielding is often measured by the lead equivalent thickness. Medical professionals should assess the level of protection needed and choose screens that meet or exceed industry standards.

2. Dimensions and Portability

Depending on the space available and the specific needs of the facility, screens should be portable and adjustable. This flexibility allows for optimal positioning during various procedures.

3. Durability and Maintenance

Selecting high-quality materials ensures that the screens withstand regular use and potential wear and tear, facilitating easier cleaning and maintenance.

4. Compliance with Standards

It’s vital to ensure that any product complies with the relevant safety regulations and standards imposed by health authorities.

Conclusion

In conclusion, x-ray protective lead rubber screens represent a critical component in the safety protocols surrounding medical imaging. They not only safeguard patients and healthcare workers but also contribute to compliance with stringent safety regulations. As the landscape of medical technology continues to evolve, integrating sophisticated protective measures becomes increasingly paramount. Investing in lead rubber screens is not just a regulatory compliance move, but a commitment to the health and safety of everyone in the healthcare environment. For comprehensive solutions related to radiation shielding, trusted providers like ovmdevice.com excel in offering a wide range of products that meet the highest standards in radiation safety.