The Importance of the Manufacture of Crankshaft in Diesel Engines

Understanding Crankshafts

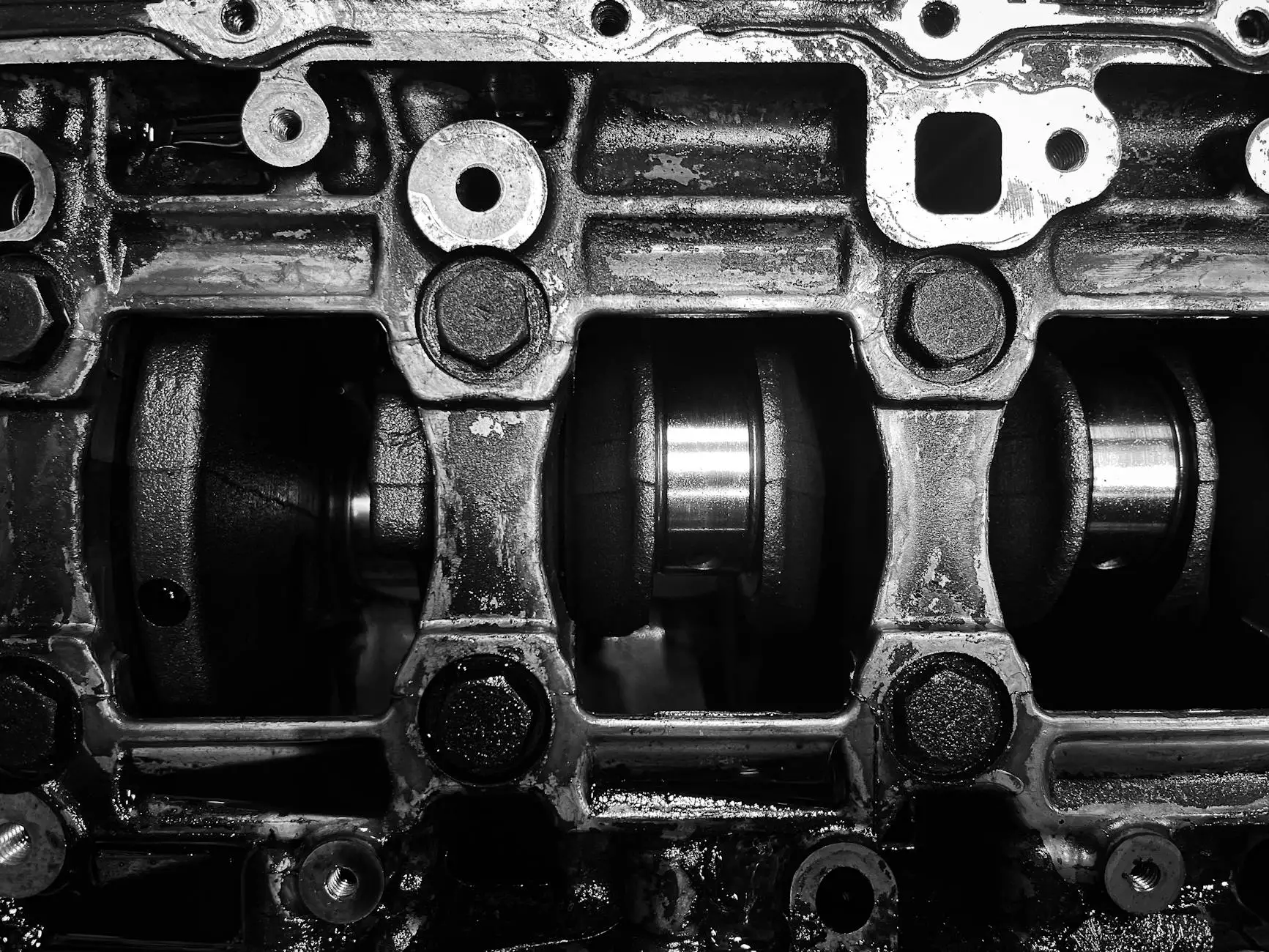

The crankshaft is a fundamental component in internal combustion engines, transforming linear motion into rotational motion. This allows the engine to convert the power generated by fuel combustion into usable mechanical energy. In diesel engines, crankshafts must endure extreme conditions, making the manufacture of crankshaft a critical aspect of engine production.

The Process of Crankshaft Manufacturing

The manufacture of crankshaft involves multiple steps to ensure precision and durability. Let's delve into the main stages:

- Material Selection: Crankshafts are typically made from high-strength materials such as forged steel or ductile iron. These materials are chosen for their ability to withstand the high stresses imposed during engine operation.

- Forging: The forging process involves shaping the metal under high pressure, which enhances the material’s strength and durability. This step is vital in ensuring that the crankshaft can handle the immense forces generated during engine cycles.

- Machining: After forging, the crankshaft undergoes precision machining. This process includes grinding and turning to achieve the exact dimensions and surface finish required. High-quality machining ensures that the crankshaft fits snugly within the engine assembly.

- Heat Treatment: Heat treatment processes such as quenching and tempering are performed to improve the mechanical properties of the crankshaft. This enhances resistance to wear and fatigue, which is crucial for longevity.

- Balancing: Post-manufacturing, the crankshaft must be balanced correctly. An unbalanced crankshaft can lead to severe vibrations, compromising engine performance and longevity. Balancing is performed to ensure smooth operation.

- Quality Control: Comprehensive inspections, including dimensional checks, non-destructive testing, and surface integrity evaluations, are conducted to guarantee the crankshaft meets the strict industry standards.

Why Quality Matters in Crankshaft Manufacturing

In the field of diesel engine parts, quality is paramount. Here’s why:

- Performance: A high-quality crankshaft contributes to the overall performance of the diesel engine. It minimizes vibrations and enhances efficiency.

- Durability: Engines equipped with well-manufactured crankshafts experience fewer breakdowns and extended operational life.

- Safety: Inferior crankshafts can lead to catastrophic engine failures, which might endanger both the operator and the equipment.

Challenges in Crankshaft Production

The manufacture of crankshaft isn’t without its challenges:

- Material Variability: The quality of raw materials can vary, affecting the performance of the final product.

- Technological Advancements: Keeping up with rapid advancements in machining technology is essential to maintaining competitiveness.

- Cost Management: Balancing cost and quality is a constant challenge; manufacturers must invest wisely to ensure durability without inflating prices excessively.

- Regulatory Compliance: Adhering to strict regulatory standards concerning emissions and safety can impose additional production challenges.

Future Trends in Crankshaft Manufacturing

As the automotive industry evolves, so does the need for innovation in the manufacture of crankshafts:

- Lightweight Materials: There is a growing trend towards using lightweight yet strong materials, such as aluminum alloys and composites, to enhance fuel efficiency.

- Advanced Manufacturing Techniques: Technologies such as additive manufacturing (3D printing) are emerging, presenting opportunities for creating complex designs that were previously not possible.

- Emphasis on Sustainability: Manufacturers are increasingly focused on sustainable practices, aiming to reduce waste and energy consumption in the manufacturing process.

- Smart Manufacturing: The integration of IoT and robotics in manufacturing will help optimize production lines, improve quality control, and reduce lead times.

Conclusion: The Essential Role of Crankshaft in Diesel Engines

The manufacture of crankshaft is a vital aspect of diesel engine production, influencing both performance and reliability. As a supplier of spare parts, understanding the intricacies of crankshaft manufacturing allows businesses to meet the demands of modern engines while providing customers with high-quality products. The journey from raw material to finished crankshaft is complex, requiring precision engineering, advanced technology, and an unwavering commitment to quality. Investing in superior manufacturing processes not only ensures optimal performance but also enhances safety and longevity in diesel engines.

When looking for quality diesel engine parts, including crankshafts, consider companies that prioritize rigorous manufacturing standards to deliver reliable products. At client-diesel.com, we are committed to excellence in the manufacture of crankshafts and other diesel engine components, ensuring your engines perform at their best.

© 2023 | Client Diesel | Quality Spare Parts Suppliers